All of us enjoy electrical

appliances, be it domestic or commercial. But we tend to forget that there is

an underlying network of cables supporting the entire system. High technology

is involved in the making these cables, which makes them withstand tough

conditions for years.

We strongly believe that basic

knowledge about the cables are a must for them who own a genset. Choosing the

manufacturer recommended Power Cable for your genset is important. To save a

few bucks we are often tempted to use cheaper options which may lead to many

issues like the ones discussed below.

Undersized cable will generate

excessive heat which may melt the protective cover of the cable leading to

hazards like fire or electric shock.

In case there is a short

circuit, an undersized cable will not withstand the fault current. The cable

may melt, burn or even cause severe damage to connected equipment even before

any tripping mechanism may work.

Powerol recommends the use of

3.5 Core Armoured Power Cable for three phase and 2 Core Armoured Power Cable

for single phase gensets.

Let us understand what this

actually is:

3.5 Core cables will have 3

stranded wires for R, Y, B Phases, with diameter X and one stranded wire for

Neutral with diameter X/2.

A 2 Core cable will have one

Phase wire and one Neutral wire of same diameter.

|

3.5 Core Cable

|

|

2 Core Cable

|

Construction of 3.5 Core and 2 Core Armoured

Cable:-

Weather Proof Coating :

Withstands every weather condition.

Steel Armour :

Provides the mechanical and tensile strength to withstand toughest conditions.

Extra Insulation :

Under the steel insulation this extra insulation lies.

Core Insulation :

Prevents short circuit. Insulation material should be XLPE if underground cable

is used.

Stranded Conductor :

These are the current carrying conductors.

CHOOSE THE

RIGHT POWER CABLE

Overheating

due to usage of undersized cables and loose thumbing causes most of the

electrical failures. Choosing the right size and type of Power Cable is a

critical technical decision. Consider every possible factors before making a

purchase decision.

The size of

Power Cables (generally referred in Sq.mm) primarily depends on the Ampere

rating of the Genset. Copper is a better conductor compared to Aluminium, they

are the best material to be considered. For the same amount current lesser

diameter of Copper cable can be used compared to Aluminium cable. Downside of

using a Copper Cable is they are heavier and costlier than the Aluminium

Cables.

While

laying the cable try to keep the bends minimum and avoid sharp bends.

Avoid

joints, use a continuous cable. In case a joint is unavoidable the work must be

done by a qualified person. Incorrect joint will lead to expensive failure in

future.

Use

right size of thimbles and proper crimping to make a proper terminal

connection.

For

proper terminal connection the contact area must be adequate.

Improper

termination will lead to local heat generation. Which will lead to failure.

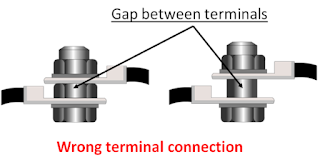

Avoid Point

connection arising out of improper position. Gaps between leads and terminals,

in such cases the Nuts or Bolts will carry the load current. Normally they are

made of Mild Steel and are not designed to carry high current.

Do consult an authorized person before purchasing the Power

Cable. Powerol has a highly competent team of genset installation specialist.

You may contact them for any guidance.

There are

large variety of Power Cable types to suit different kind of operation.

Including all of them in this blog will make it little overwhelming for the

reader. If you are interested to know more about Power Cables, do let us know

in the comments section, we will be happy to help you.